Productivity in Automotive Industry

Key Performance Indicators (KPIs) in Automotive Manufacturing:

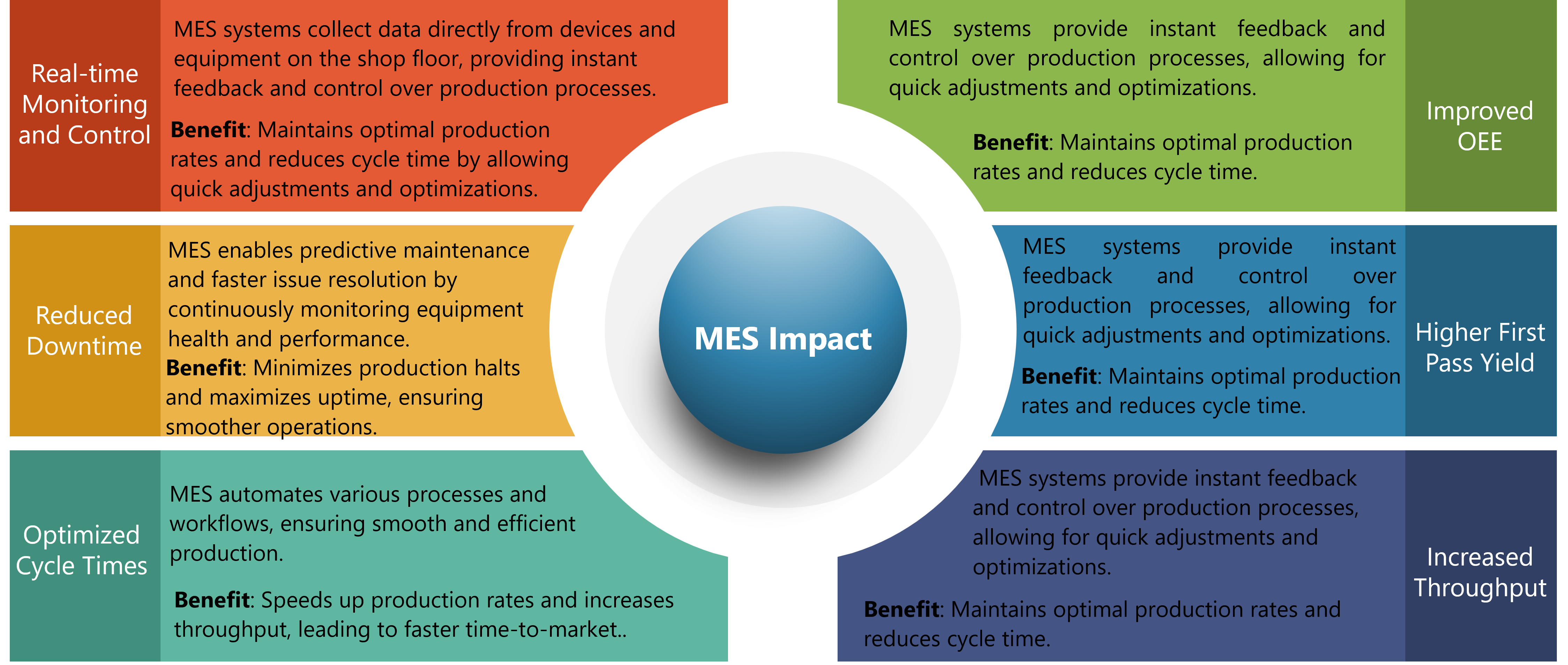

- Production Volume: The total number of units produced within a specified time frame.

- Importance: Higher production volumes indicate better utilization of resources and increased capacity to meet market demand.

- Cycle Time: The total time it takes to produce a single unit from start to finish.

- Importance: Reducing cycle time leads to faster production rates and increased throughput.

- Downtime: The amount of time production is halted due to equipment failures, maintenance, or other disruptions.

- Importance: Minimizing downtime ensures continuous production and maximizes operational efficiency.

- Overall Equipment Effectiveness (OEE): A composite KPI that measures the efficiency of equipment, considering availability, performance, and quality.

- Importance: High OEE indicates optimal use of machinery and minimal losses in production processes.

- First Pass Yield (FPY): The percentage of products that meet quality standards without requiring rework.

- Importance: High FPY reflects superior production quality and reduces costs associated with defects and rework.

- Throughput: The rate at which products are produced and move through the production line.

- Importance: Higher throughput indicates efficient use of resources and faster time-to-market for finished products.

MES Impact on Productivity

Manufacturing Execution Systems (MES) play a pivotal role in enhancing productivity in the automotive industry by providing real-time data, streamlining processes, and enabling better decision-making. How MES can impact key productivity KPIs:

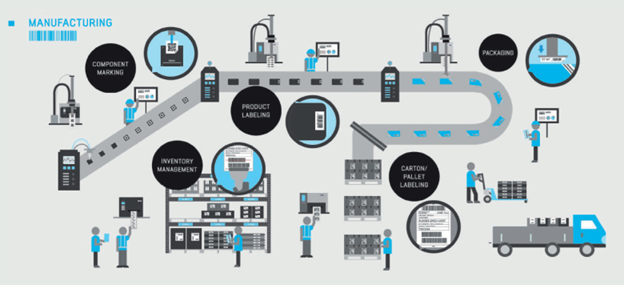

Top features of our MES for Automotive Industry

- Real-time Data Collection: Our MES collects data directly from devices and equipment on the shop floor without any manual intervention. This ensures that you have accurate and up-to-date information at all times.

- Benefit: Enables immediate decision-making and quick responses to any production issues, enhancing overall efficiency.

- Production Scheduling: Optimize production plans and adjust schedules dynamically based on real-time data.

- Benefit: Ensures that production meets demand without overproduction or delays.

- Quality Management: Real-time quality checks and defect tracking directly from the production line.

- Benefit: Enhances product quality and reduces the likelihood of recalls.

- Traceability: Complete tracking of parts and materials throughout the supply chain with automatic data capture.

- Benefit: Ensures compliance and improves the ability to quickly respond to any quality issues.

- Maintenance Management: Predictive and preventive maintenance alerts based on real-time equipment performance data.

- Benefit: Reduces unexpected downtimes and extends the life of machinery.

- Performance Analysis: Detailed analytics and reporting on various aspects of the production process.

- Benefit: Identifies bottlenecks and areas for improvement, driving continuous improvement initiatives.

- Workforce Management: Efficient labor management and shift scheduling based on real-time production needs.

- Benefit: Ensures optimal use of human resources and maintains high productivity levels. Case Studies

By implementing an MES like our Smart, automotive manufacturers can significantly boost their productivity, ensuring they stay competitive and meet the ever-growing demands of the market.

Success Stories in Automotive Manufacturing

The “Smart Station” project has been put into operation with 4 stations in the Fiat Automobile Factory Assembly Unit. Within the scope of the project, operations to be carried out during the assembly process are managed by Smart Stations and data related to the operations can be monitored instantly from the production site.

In the operations carried out by the Smart Stations put into operation, the equipment used in the operations are commanded by communicating with two different facilities via the Digital I/Os of the Stations, one charged squeezer via Radio Frequency and one electronic squeezer via serial port. For errors that occur during the operation process, the operator can enter the errors defined in the operation via the Smart Station’s touch screen. In this way, it is aimed to create an infrastructure for the analysis and improvement of the errors that occur.

Orders have been received for the project to be spread to all assembly lines and production is ongoing.