Productivity in Automotive Industry

Key Performance Indicators (KPIs) in Food and Beverage Manufacturing:

- Production Volume:

- The total number of units produced within a specified time frame.

- Importance: Higher production volumes indicate better utilization of resources and increased capacity to meet market demand.

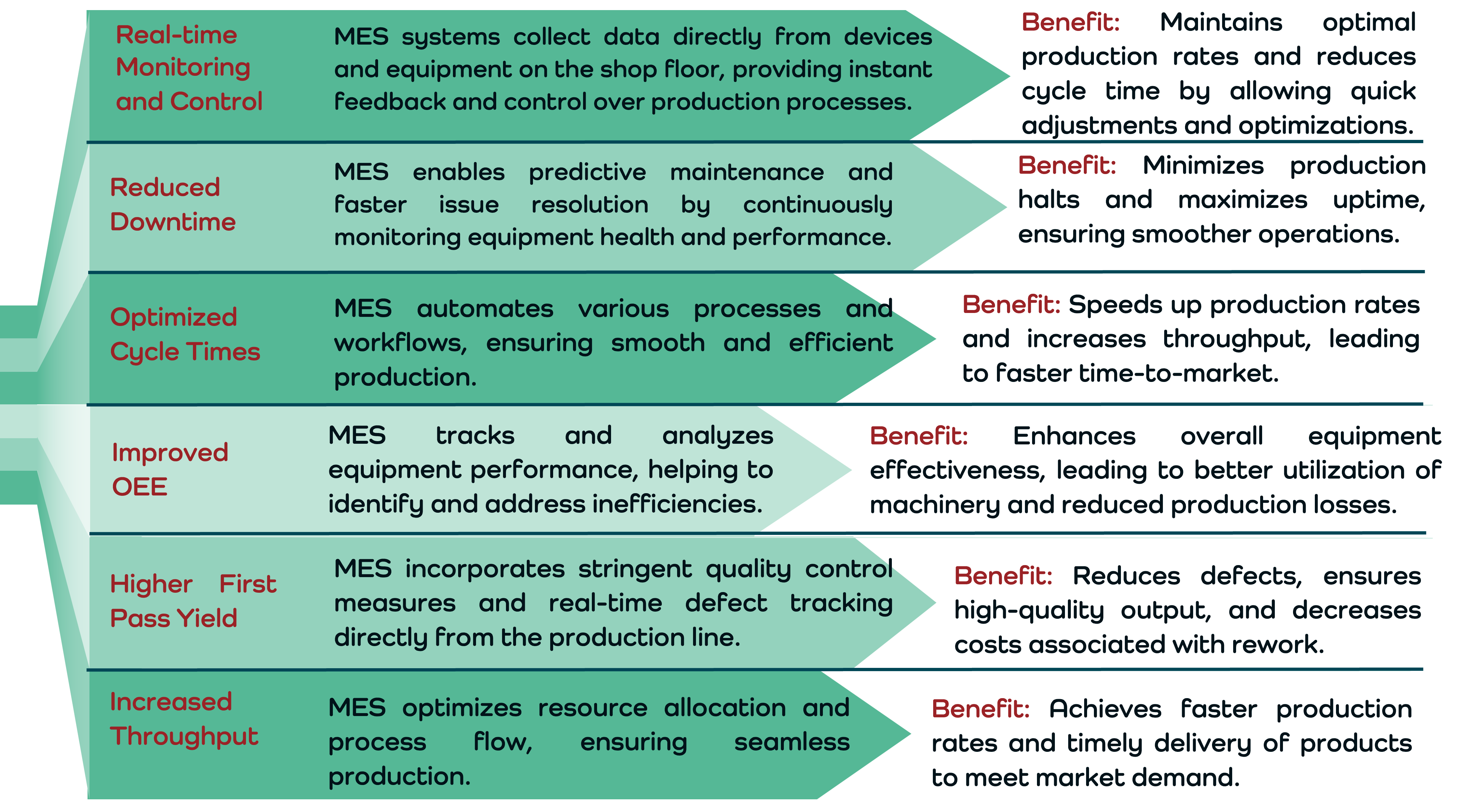

- Cycle Time:

- The total time it takes to produce a single unit from start to finish.

- Importance: Reducing cycle time leads to faster production rates and increased throughput.

- Downtime:

- The amount of time production is halted due to equipment failures, maintenance, or other disruptions.

- Importance: Minimizing downtime ensures continuous production and maximizes operational efficiency.

- Overall Equipment Effectiveness (OEE):

- A composite KPI that measures the efficiency of equipment, considering availability, performance, and quality.

- Importance: High OEE indicates optimal use of machinery and minimal losses in production processes.

- First Pass Yield (FPY):

- The percentage of products that meet quality standards without requiring rework.

- Importance: High FPY reflects superior production quality and reduces costs associated with defects and rework.

- Throughput:

- The rate at which products are produced and move through the production line.

- Importance: Higher throughput indicates efficient use of resources and faster time-to-market for finished products.

MES Impact on Productivity

Manufacturing Execution Systems (MES) play a pivotal role in enhancing productivity in the food and beverage industry by providing real-time data, streamlining processes, and enabling better decision-making. Here’s how MES can impact key productivity KPIs:

Top features of our MES in Food and Beverage Industry

- Real-time Data Collection: Our MES collects data directly from devices and equipment on the shop floor without any manual intervention. This ensures that you have accurate and up-to-date information at all times.

- Production Scheduling: Optimize production plans and adjust schedules dynamically based on real-time data.

- Quality Management: Real-time quality checks and defect tracking directly from the production line.

- Traceability: Complete tracking of ingredients and materials throughout the supply chain with automatic data capture.

- Maintenance Management: Predictive and preventive maintenance to avoid unexpected downtimes.

- Performance Analysis: Detailed analytics and reporting to identify improvement opportunities.

- Workforce Management: Efficient labor management and shift scheduling based on real-time production needs.

By implementing an MES like our Smart, automotive manufacturers can significantly boost their productivity, ensuring they stay competitive and meet the ever-growing demands of the market.

Success Stories in Automotive Manufacturing

Coca-Cola, one of the world's largest beverage manufacturers, faced challenges with the reliability and efficiency of their mobile equipment within their manufacturing and distribution facilities.

Objectives

Enhance Equipment Reliability: Improve the uptime and reliability of mobile equipment, such as forklifts and automated guided vehicles.

- Optimize Maintenance: Implement predictive maintenance to reduce unexpected breakdowns and maintenance costs.

- Boost Operational Efficiency: Streamline operations and enhance productivity through real-time monitoring and data-driven decision-making.

Solution

We provided a comprehensive solution that included:

- IoT Integration: Deployed IoT sensors on all mobile equipment to collect real-time operational data.

- Advanced Analytics: Utilized machine learning algorithms to analyze data, predict potential failures, and optimize maintenance schedules.

- User Training: Conducted extensive training for Coca-Cola’s staff to effectively use the new tools and interpret the data.

Implementation

The project was executed in several phases:

- Pilot Phase: A pilot implementation was carried out in one of Coca-Cola’s major facilities to test and refine the system.

- Full Deployment: Following the successful pilot, the solution was rolled out across multiple facilities.

- Continuous Support: Provided ongoing support and updates to ensure the system’s optimal performance.

Results

- Increased Uptime: Equipment downtime was reduced by 20%, significantly improving production schedules.

- Cost Savings: Maintenance costs were cut by 15% due to the shift from reactive to predictive maintenance.

- Operational Efficiency: Enhanced real-time visibility into equipment status and operations, leading to a 10% increase in overall productivity.

- Data-Driven Decisions: Coca-Cola’s management gained valuable insights from the data, allowing for more informed decision-making.