Productivity in Home Appliance

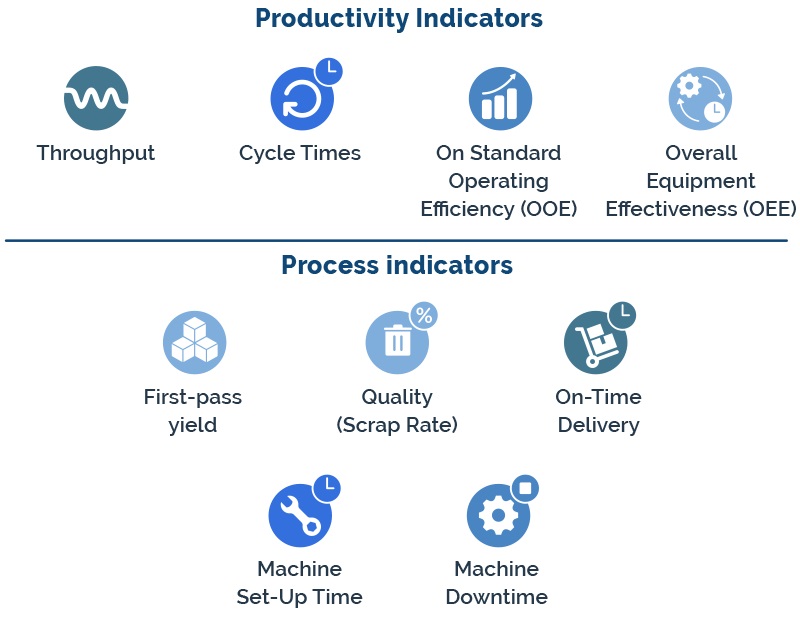

ey Performance Indicators (KPIs) in Home Appliance Manufacturing:

1. Production Volume:

- The total number of units produced within a specified time frame.

- Importance: Higher production volumes indicate better utilization of resources and increased capacity to meet market demand.

2. Cycle Time:

- The total time it takes to produce a single unit from start to finish.

- Importance: Reducing cycle time leads to faster production rates and increased throughput.

3. Downtime:

- The amount of time production is halted due to equipment failures, maintenance, or other disruptions.

- Importance: Minimizing downtime ensures continuous production and maximizes operational efficiency.

4. Overall Equipment Effectiveness (OEE):

- A composite KPI that measures the efficiency of equipment, considering availability, performance, and quality.

- Importance: High OEE indicates optimal use of machinery and minimal losses in production processes.

5. First Pass Yield (FPY):

- The percentage of products that meet quality standards without requiring rework.

- Importance: High FPY reflects superior production quality and reduces costs associated with defects and rework.

6. Throughput:

- The rate at which products are produced and move through the production line.

- Importance: Higher throughput indicates efficient use of resources and faster time-to-market for finished products.

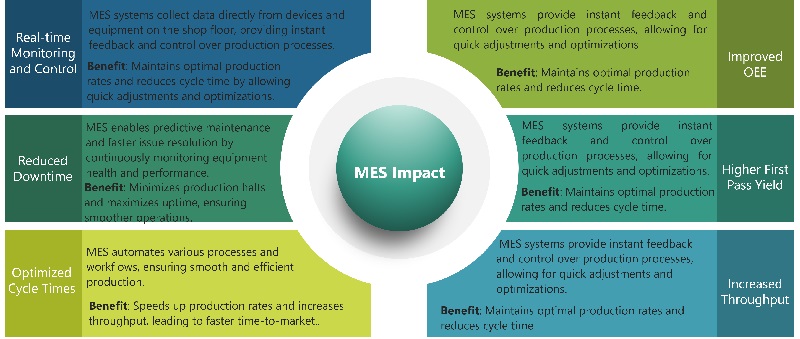

MES Impact on Productivity

Manufacturing Execution Systems (MES) play a pivotal role in enhancing productivity in the automotive industry by providing real-time data, streamlining processes, and enabling better decision-making. How MES can impact key productivity KPIs:

Features of our MES for Home Appliance Industry

- Real-time Data Collection:

Our MES collects data directly from devices and equipment on the shop floor without any manual intervention. This ensures that you have accurate and up-to-date information at all times.

- Benefit:

Enables immediate decision-making and quick responses to any production issues, enhancing overall efficiency.

- Production Scheduling:

Optimize production plans and adjust schedules dynamically based on real-time data.

- Quality Management:

Real-time quality checks and defect tracking directly from the production line.

- Traceability:

Complete tracking of materials and components throughout the supply chain with automatic data capture.

- Maintenance Management:

Predictive and preventive maintenance to avoid unexpected downtimes.

- Performance Analysis:

Detailed analytics and reporting to identify improvement opportunities.

- Workforce Management:

Efficient labor management and shift scheduling based on real-time production needs.

By implementing an MES like our Smart, automotive manufacturers can significantly boost their productivity, ensuring they stay competitive and meet the ever-growing demands of the market.

Success Stories in Home appliance industry

Even though breakdowns are minimized, short breakdowns are inevitable. Our clients were unable to track and understand the reasons behind these minor disruptions. Sometimes, their production lines did not meet targets despite the absence of significant breakdowns.

With the Efficiency Dashboard system developed by us, we can track millions of signals from the shop floor, collect, and report them on our IoT platform. This allows us to identify the causes of these breakdowns and intervene promptly, thereby increasing efficiency.

One of the primary reasons clients prefer us is our team of qualified engineers. We stay current with today's technology and trends, incorporating them into our systems and products. More importantly, our clients are impressed by our enthusiasm for their projects and the motivation we bring to the table.

Our clients have seen significant gains in two key areas. Post-implementation, their quality levels have reached unprecedented heights, and they no longer experience scraps or faulty manufacturing. There is a strong synergy and cooperation between the software and hardware departments at our company.

We assure that the service we provide is of the highest level. Additionally, we do not limit ourselves to meeting our clients' requirements; we consistently exceed them by developing further specifications and delivering beyond what is asked.